Textile serves, when applied to Litz wires, act as an optional layer of added mechanical protection for the overall conductor. Serves are particularly effective at protecting the enamel layer on the individual strands of the conductor from abrasion during further processing. The serve acts as a physical barrier between the enamel layer and any contact points that may be present in the wire path of a cutting & terminating operation for the Litz wire. Like the fiberglass braid on braided silicone wire, the serve helps to protect the soft enamel insulation underneath from sharp edges and pinch points in the wire path. It should be noted, however, that textile serves are not intended to act as electrical insulating layers and will not replace electrical insulation where required.

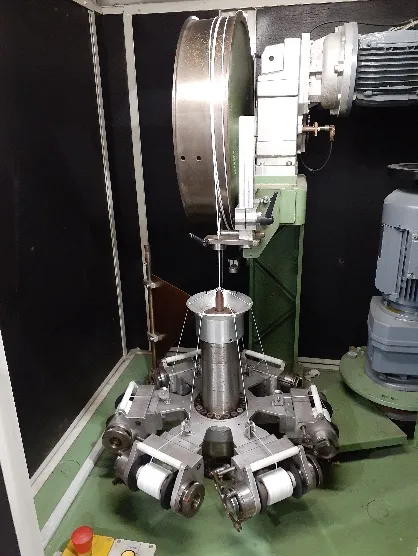

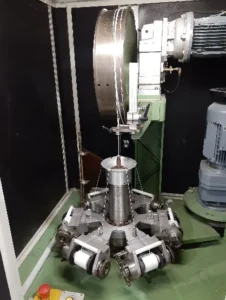

At Rubadue Wire, we have the expertise and the equipment to meet your needs for served Litz wires. We apply serves to Litz conductors as small as 0.005” [0,13mm] in diameter, and we have recently expanded our manufacturing capabilities for serving larger Litz conductors to include diameters greater than .340” [8,63mm].

Some things to consider when evaluating whether a serve is appropriate for your application:

- Number of Serve Layers Needed: Litz wire can be supplied with one or two layers of a textile serve for added mechanical strength and protection.

- Space Availability: A single nylon serve adds an average of 0.002” (0,051mm) to the diameter of a Litz wire. A double nylon serve adds an average of 0.004” (0,102mm) to the diameter of a Litz wire. Other serve materials may have an even greater impact on the outside diameter of the Litz wire. Depending on the amount of space available in a winding, the inclusion of a serve could impact the number of turns that is achievable with the winding.

- Operating Temperature: Nylon serves are commonly used with Class F (155°C) Litz conductors. Windings with higher temperature ratings may require higher temperature serve materials, such as PTFE, Nomex® or fiberglass.*

| Serve Material | Recommended Maximum Operating Temp. | Approximate increase in conductor diameter when served | Solderable? | Cost | |

| Single Serve (in) | Double Serve (in) | ||||

| Cotton | 105°C | 0.005 | 0.010 | No | Low |

| Silk | 110°C | 0.002 | 0.004 | Yes | High |

| Nylon | 155°C | 0.002 | 0.004 | Yes | Low |

| Polyester | 155°C | 0.004 | 0.008 | Yes | Mid |

| Nomex® | 204°C | 0.003 | 0.006 | No | High |

| PTFE | 260°C | 0.008 | 0.016 | No | High |

| Fiberglass | 260°C | 0.005 – 0.010 | 0.010 – 0.020 | No | High |

- Flexibility Needs: Some stranded Litz conductors may experience a loss of flexibility due to the inclusion of a serve in the construction. The tightly wound fibers of the serve restrict the ability of the strands and rope-lay members in a stranded conductor to move around and flatten out when the wire is bent, resulting in a loss of flexibility in the conductor. This effect is particularly pronounced and noticeable with Type 2 Litz conductors, which can be somewhat stiff to begin with.

When a Type 2 Litz is required, Rubadue Wire has the expertise to ensure the Litz conductor is designed and manufactured to maximize flexibility to ensure proper winding characteristics.

Our single and double nylon serves are recognized by UL in Rubadue’ s OBMW2 Magnet Wire – Component file, E190291 and are suitable for use in many UL approved Electrical Insulation Systems.

Need assistance in determining if a textile served Litz construction is appropriate for your application? Contact our knowledgeable sales and engineering teams to discuss your application at sales@rubadue.comor +1(970) 351-6100.

* Nomex® is a trademark of DuPont de Nemours, Inc.

You May Like

A Brief Explanation of Litz Diameters and Tolerances

For engineers in the transformer industry who are used to working with solid conductor winding wires, the larger diameters and wider tolerances on Litz wires may come as a bit of a shock. With Litz

Company Alert: Monday, Jan. 22, 2024

The Telephone & Internet service at the Rubadue Wire manufacturing facility in Loveland, Colorado has been disrupted, due to local weather conditions. Please utilize email for all communications until further notice. For Sales & General